How an Industrial Coffee Grinder Can Improve Your Product Quality

Wiki Article

Industrial Coffee Grinder Overview: Boost Effectiveness and Quality

In the affordable landscape of coffee manufacturing, choosing the appropriate industrial coffee grinder plays a pivotal function in boosting both effectiveness and item quality. Comprehending the subtleties of various mill kinds and essential attributes-- such as customizable work setups and robust building and construction-- can considerably affect the last flavor profile of the coffee. In addition, the optimization of the grinding process, combined with attentive maintenance, is vital for maintaining performance in time. As we explore these crucial aspects, it comes to be evident that the implications prolong past plain equipment choice, affecting general service success in manner ins which necessitate closer examination.Recognizing Grinder Kinds

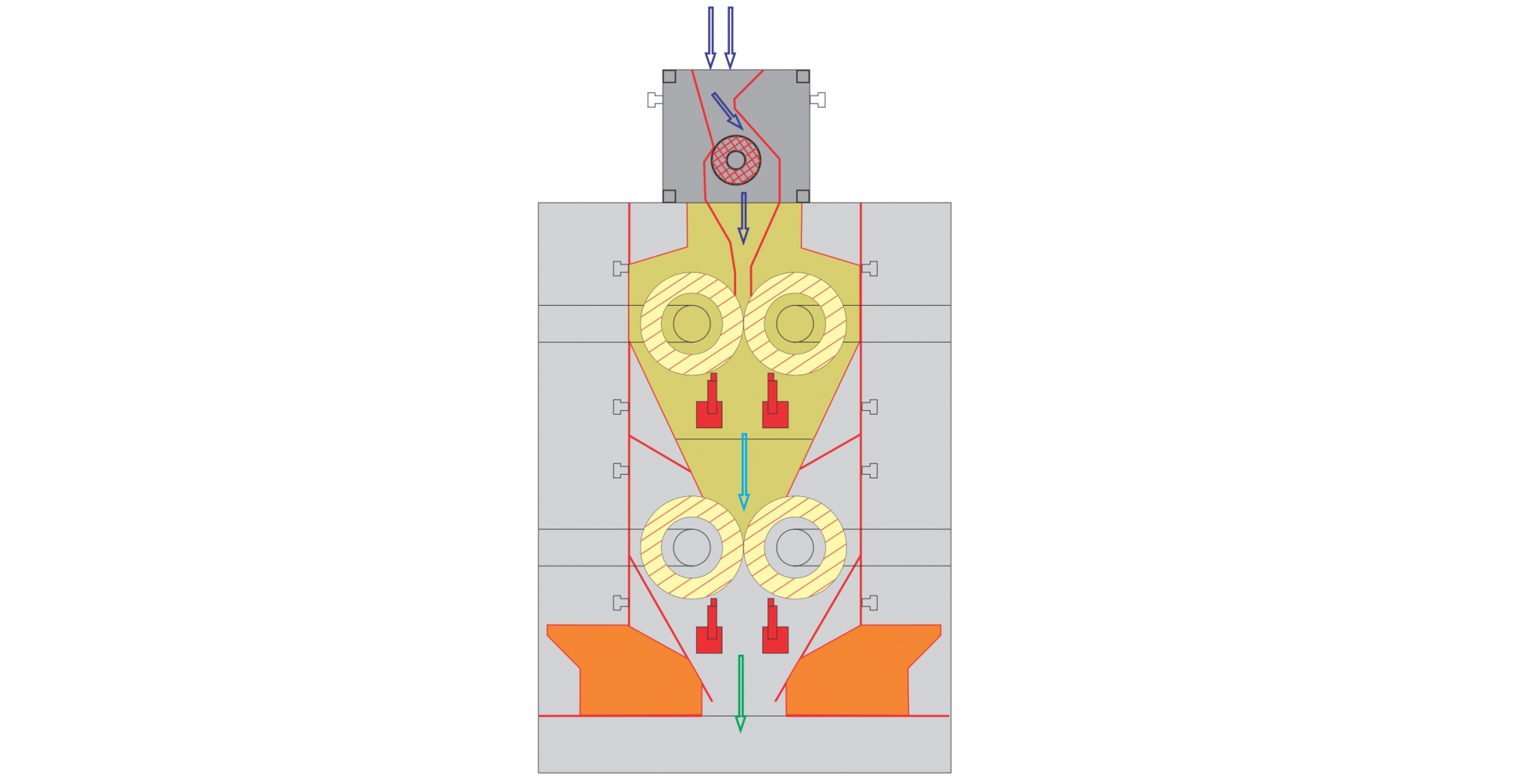

When choosing a commercial coffee grinder, understanding the different types available is important for enhancing both flavor removal and operational efficiency. The 2 primary kinds of grinders are blade mills and burr mills.

Inevitably, selecting the ideal kind of mill is essential to preserving high quality and performance in coffee manufacturing, making it important for businesses to purchase high-quality burr grinders for ideal outcomes.

Key Functions to Take Into Consideration

Selecting an industrial coffee mill calls for careful consideration of a number of vital features that can considerably affect both efficiency and the overall coffee experience. One of the main facets to review is the grinding mechanism. Burr grinders are typically liked over blade mills, as they provide a consistent grind size, which is vital for optimal removal and flavor.One more vital function is the grinder's capability. A flexible mill with numerous settings enables you to customize the work dimension to various developing techniques, improving the coffee's flavor profile.

The building material also plays a duty in sturdiness and maintenance. Stainless steel parts usually use durability and are simpler to clean, which is crucial for keeping hygiene standards. Assess the mill's sound level, specifically in a hectic coffee shop or production setting, where excessive sound can be disruptive. Purchasing a grinder that stabilizes these functions can significantly boost both operational performance and the high quality of the coffee served.

Optimizing Grinding Process

To attain the most effective cause coffee prep work, optimizing the grinding process is essential. The work dimension substantially affects removal, taste, and general top quality of the brewed coffee. Different brewing approaches require certain work dimensions; for instance, espresso requires a great work, while French press necessitates a rugged structure. Recognizing the relationship between grind size and developing technique is the initial action in optimization.

In addition, monitoring the grinding speed can optimize the process. Slower grinding frequently creates less heat, preserving delicate flavors and fragrances. Conversely, much faster grinding may generate excessive heat, adversely impacting the coffee's quality.

Upkeep and Treatment Tips

Correct maintenance and care of commercial coffee mills are crucial for ensuring optimum efficiency and durability. Routine cleaning is the structure of upkeep; residue buildup can affect taste and grinding effectiveness. It is a good idea to clean the mill after each usage, wiping down the exterior and getting rid of any type of coffee grounds from the burrs.Additionally, evaluate the grinding burrs for deterioration. Boring burrs can compromise work consistency, so they should be changed as needed. Industrial Coffee Grinder. Periodically adjusting the grinder is also critical, as this keeps the preferred work size for various developing approaches

Lubrication of moving components must be carried out according to the supplier's specs, as this decreases rubbing and extends the life of the equipment. It is important to utilize food-grade lubricants to make certain security and conformity with health laws.

Finally, maintain the grinder in a completely dry and stable atmosphere to prevent corrosion and deterioration. By adhering to these upkeep and care ideas, drivers can improve the performance of their industrial coffee mills while guaranteeing high-quality result and extended operational life.

Return on Financial Investment Evaluation

Assessing the roi (ROI) for industrial coffee grinders is critical for services seeking to enhance their coffee production abilities. An extensive ROI analysis helps establish the economic practicality of purchasing top quality grinders, permitting services to consider the initial costs against try this site potential gains.To carry out a detailed ROI analysis, services must think about a number of crucial variables. Initially, analyze the acquisition cost of the mill, including setup and any required adjustments to existing infrastructure. Next off, compute functional costs, including power usage, maintenance expenses, and labor performance renovations. High-performance grinders frequently lead to reduced grinding time and raised throughput, which can substantially improve productivity.

Additionally, take into consideration the effect on her latest blog product high quality. Industrial Coffee Grinder. Superior grinders produce a more regular grind dimension, which can improve flavor accounts and client fulfillment, eventually driving sales. By raising the high quality of the end product, organizations can validate greater prices, leading to boosted revenue

Final Thought

In summary, an industrial coffee grinder plays a critical role in enhancing both efficiency read review and product quality within coffee production. Ultimately, the strategic financial investment in a trusted mill adds dramatically to boosted profits and competition in the coffee market.In the competitive landscape of coffee production, picking the appropriate commercial coffee grinder plays a critical role in boosting both performance and item high quality. The 2 primary kinds of grinders are blade mills and burr mills. Within the burr mill classification, there are flat burr grinders and conelike burr mills, each with its benefits. Burr grinders are typically preferred over blade mills, as they supply a consistent work dimension, which is important for optimal removal and flavor.

In summary, a commercial coffee grinder plays a pivotal duty in improving both efficiency and item quality within coffee manufacturing.

Report this wiki page